Dive into Just-In-Time Inventory Management!

Welcome to the exciting world of Just-In-Time inventory management! If you’re a beginner looking to streamline your inventory processes and improve efficiency, you’ve come to the right place. Just-In-Time (JIT) inventory management is a strategy that focuses on keeping inventory levels low and only ordering or producing goods when they are needed. This approach can help businesses reduce waste, cut costs, and improve overall productivity.

So, how do you get started with JIT inventory management? The key is to understand the principles behind this strategy and how to implement them effectively in your own business. Let’s dive in and explore the basics of JIT inventory management!

First and foremost, it’s important to understand the concept of just-in-time. This means that inventory is ordered or produced just in time to meet customer demand, rather than being stockpiled in a warehouse. By keeping inventory levels low and only ordering what is needed, businesses can reduce the risk of overstocking and minimize storage costs.

One of the main benefits of JIT inventory management is its ability to minimize waste. When inventory levels are kept low, businesses are less likely to end up with excess or obsolete inventory that needs to be disposed of. This can help businesses save money and improve their bottom line.

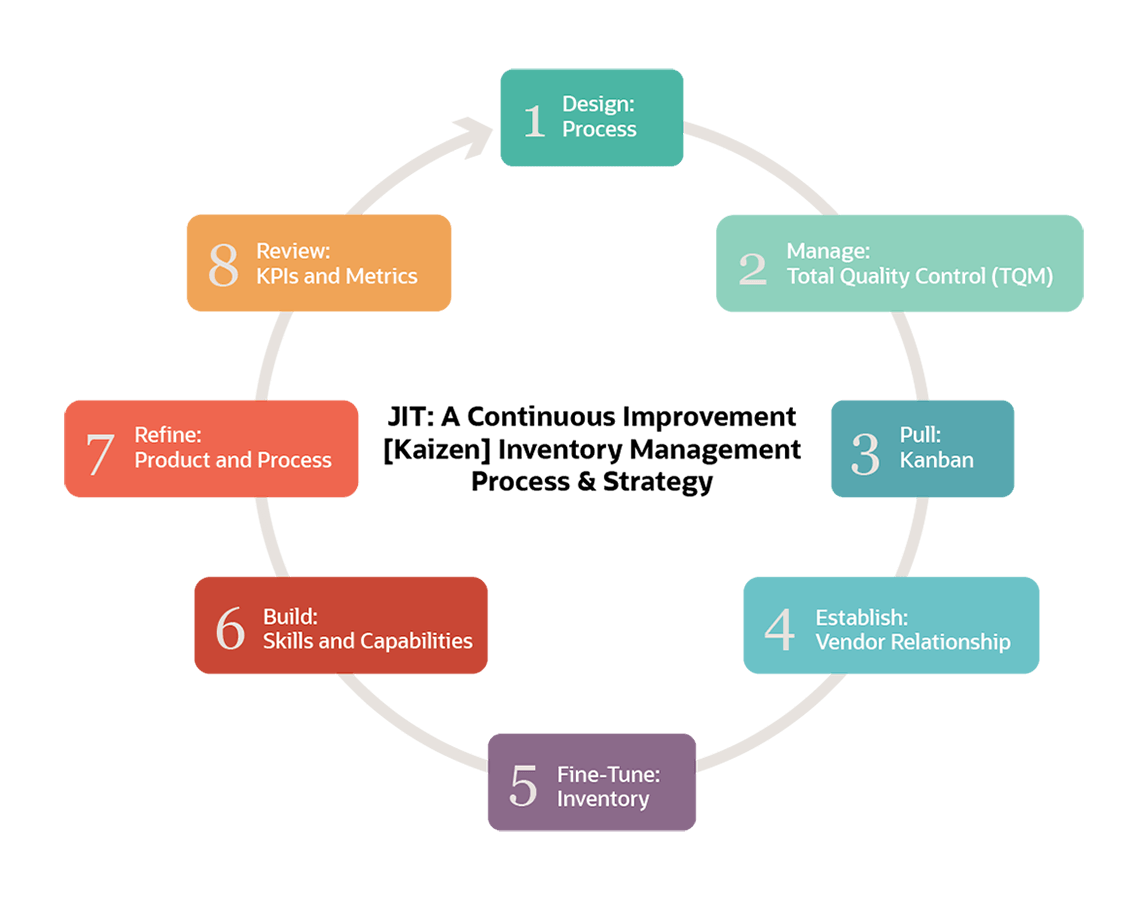

Image Source: netsuite.com

Another key principle of JIT inventory management is continuous improvement. By constantly evaluating and refining your inventory processes, you can identify areas for improvement and make adjustments to increase efficiency and reduce waste. This iterative approach can help businesses stay competitive and adapt to changing market conditions.

To successfully implement JIT inventory management in your business, you’ll need to establish strong relationships with your suppliers. Communication is key when it comes to JIT, as you’ll need to work closely with your suppliers to ensure that materials and goods are delivered on time and in the right quantities. Building trust and collaboration with your suppliers can help you achieve a seamless JIT system.

In addition to working closely with your suppliers, it’s important to invest in technology that can support your JIT inventory management efforts. Inventory management software can help you track inventory levels, monitor demand, and automate ordering processes. By leveraging technology, you can streamline your operations and improve efficiency.

When implementing JIT inventory management, it’s important to remember that change takes time. Transitioning to a JIT system may require adjustments to your current processes and workflows, but the benefits can be well worth the effort. By staying committed to continuous improvement and embracing change, you can set your business up for long-term success.

In conclusion, Just-In-Time inventory management is a powerful strategy that can help businesses reduce waste, cut costs, and improve efficiency. By understanding the principles of JIT and implementing them effectively in your own business, you can streamline your inventory processes and drive success. So, dive into JIT inventory management today and embark on a journey towards greater productivity and profitability!

Embark on Your JIT Journey Today!

Are you ready to revolutionize your inventory management system and streamline your operations? If so, then it’s time to embark on your Just-In-Time (JIT) journey today! Just-In-Time inventory management is a powerful strategy that can help you reduce waste, lower costs, and improve efficiency in your business. In this beginner’s guide, we will walk you through the basics of JIT and show you how to get started on your JIT journey.

To begin your JIT journey, the first step is to understand the core principles of Just-In-Time inventory management. At its core, JIT is all about producing only what is needed, when it is needed, and in the amount needed. This means eliminating excess inventory, reducing lead times, and increasing the flexibility of your production processes. By implementing JIT, you can improve your inventory turnover, reduce storage costs, and respond more quickly to changes in demand.

One of the key benefits of JIT is its ability to reduce waste in your operations. By only producing what is needed, you can minimize the amount of excess inventory sitting idle on your shelves. This can help you save money on storage costs, reduce the risk of obsolescence, and improve cash flow in your business. Additionally, JIT can help you identify and eliminate inefficiencies in your production processes, leading to a more streamlined and cost-effective operation.

Another important aspect of JIT is its focus on continuous improvement. In order to successfully implement JIT, you need to be constantly monitoring and refining your processes to identify areas for improvement. By embracing a culture of continuous improvement, you can drive efficiency and innovation in your business, leading to long-term success and sustainability.

So, how can you get started on your JIT journey today? The first step is to assess your current inventory management practices and identify areas for improvement. Take a close look at your current inventory levels, lead times, and production processes to pinpoint any inefficiencies or bottlenecks in your operations. Once you have identified areas for improvement, you can begin implementing changes to move towards a more JIT-focused inventory management system.

One strategy for implementing JIT is to work closely with your suppliers to establish more efficient supply chains. By working with your suppliers to reduce lead times and improve delivery schedules, you can ensure that you have the right amount of inventory on hand at all times. This can help you minimize stockouts, reduce excess inventory, and improve the overall efficiency of your operations.

Another key aspect of JIT is the use of kanban systems to manage inventory levels and production schedules. Kanban is a visual scheduling system that helps you track inventory levels, monitor production progress, and identify potential bottlenecks in your processes. By implementing a kanban system, you can improve communication and coordination between different departments, leading to a more efficient and responsive operation.

Overall, embarking on your JIT journey can help you transform your inventory management system and drive efficiency and innovation in your business. By embracing the core principles of JIT, focusing on waste reduction and continuous improvement, and implementing strategies like working with suppliers and using kanban systems, you can streamline your operations and position your business for long-term success. So, what are you waiting for? It’s time to embark on your JIT journey today and revolutionize your inventory management practices!

A Beginner’s Guide to Just-In-Time Inventory Management