Maximizing Productivity: Top Strategies for Inventory Management

In the fast-paced world of warehouse management, maximizing productivity is key to running a successful operation. With the constant influx of inventory coming in and out, it’s crucial to have efficient strategies in place to ensure smooth operations. Here are some top strategies for inventory management that can help enhance productivity in your warehouse:

1. Utilize inventory management software: Investing in a reliable inventory management software can streamline the process of tracking and monitoring inventory levels. With features like real-time data updates and automated alerts for low stock levels, you can stay on top of your inventory and prevent stockouts.

2. Implement barcode scanning technology: Barcode scanning technology can greatly improve the accuracy and efficiency of inventory management. By scanning barcodes on products, you can quickly update inventory levels and track items as they move through the warehouse. This reduces the likelihood of human errors and saves time on manual data entry.

3. Create an organized storage system: A well-organized storage system is essential for maximizing productivity in the warehouse. Implementing a system that categorizes products based on size, weight, and demand can make it easier for workers to locate items quickly. Consider using shelving units, bins, and labeling systems to keep inventory organized and easily accessible.

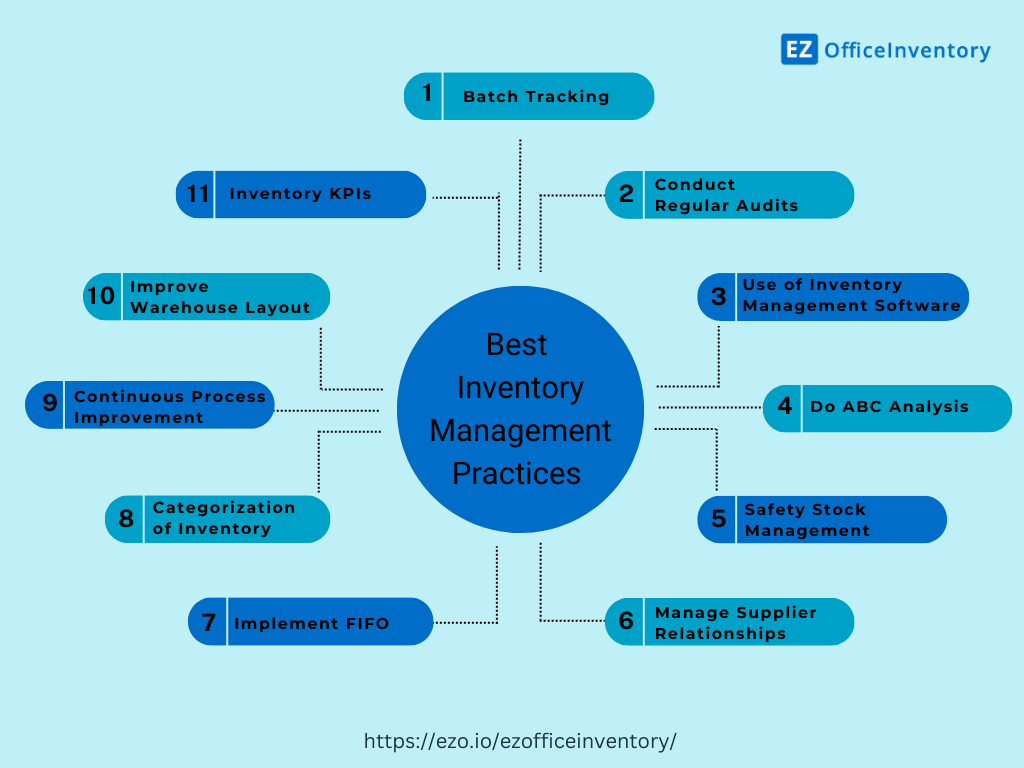

Image Source: ezo.io

4. Adopt a Just-In-Time (JIT) inventory system: Just-In-Time inventory management is a strategy that involves ordering and receiving inventory only when it is needed. By reducing excess inventory levels, you can free up valuable warehouse space and minimize the risk of overstocking. This can help streamline operations and improve overall efficiency.

5. Conduct regular inventory audits: Regular inventory audits are essential for maintaining accurate inventory levels and identifying any discrepancies. By conducting audits on a regular basis, you can ensure that your inventory data is up to date and accurate. This can help prevent inventory shortages, overstocking, and other issues that can impact productivity.

6. Train employees on best practices: Proper training is key to maximizing productivity in inventory management. Make sure your employees are well-trained on how to use inventory management software, barcode scanning technology, and other tools effectively. By providing ongoing training and support, you can empower your team to work more efficiently and effectively.

7. Optimize picking and packing processes: Streamlining the picking and packing processes can help improve productivity in the warehouse. Consider implementing strategies like batch picking, zone picking, and automated packing systems to reduce the time it takes to fulfill orders. This can help increase order accuracy and fulfillment speed, ultimately enhancing overall efficiency.

8. Monitor key performance indicators (KPIs): Tracking key performance indicators related to inventory management can help you identify areas for improvement and measure the success of your strategies. Monitor metrics like inventory turnover rate, order fulfillment time, and accuracy rates to assess the efficiency of your warehouse operations. Use this data to make informed decisions and optimize processes for better productivity.

By implementing these top strategies for inventory management, you can enhance productivity in your warehouse and optimize operations for success. From utilizing inventory management software to optimizing picking and packing processes, there are plenty of ways to streamline your inventory management practices and improve efficiency. Stay proactive, stay organized, and stay focused on maximizing productivity in your warehouse.

Efficient Warehousing: Best Practices to Boost Efficiency

In the fast-paced world of inventory management, efficiency is key to success. Whether you are a small business or a large corporation, optimizing your warehouse operations can lead to increased productivity and cost savings. By implementing best practices in efficient warehousing, you can streamline processes, minimize errors, and maximize the use of your space and resources.

One of the most important aspects of efficient warehousing is proper organization. Keeping your inventory well-organized can help prevent lost items, reduce picking errors, and improve overall efficiency. Utilizing shelving systems, labeling products clearly, and implementing a logical layout can make it easier for employees to locate items quickly and accurately.

In addition to organization, utilizing technology can greatly improve warehouse efficiency. Implementing a warehouse management system (WMS) can help track inventory levels, automate processes, and provide real-time data for better decision-making. Barcode scanning, RFID technology, and automated picking systems can also help streamline operations and reduce manual errors.

Another key aspect of efficient warehousing is proper inventory management. This includes conducting regular audits, cycle counting, and implementing a first-in, first-out (FIFO) system to ensure that products are moving efficiently through the warehouse. By keeping track of inventory levels and replenishing stock as needed, you can prevent stockouts, reduce excess inventory, and improve overall efficiency.

Utilizing space efficiently is also crucial for optimizing warehouse operations. By maximizing vertical space with mezzanines or racking systems, you can make the most of your warehouse space and reduce the need for expansion. Implementing a layout that minimizes travel time for employees and utilizes space effectively can also help improve workflow and productivity.

Furthermore, investing in employee training and development is essential for efficient warehousing. Properly trained employees are more likely to work efficiently, accurately, and safely, leading to a more streamlined operation overall. By providing ongoing training and education, you can ensure that your workforce is equipped with the skills and knowledge needed to succeed in their roles.

Lastly, continuous improvement is key to maintaining efficient warehousing practices. By regularly reviewing processes, identifying areas for improvement, and implementing changes as needed, you can adapt to changing business needs and stay ahead of the competition. Encouraging feedback from employees, monitoring key performance indicators, and benchmarking against industry standards can help drive continuous improvement and maintain high levels of efficiency in your warehouse.

In conclusion, efficient warehousing is essential for optimizing warehouse efficiency and achieving success in inventory management. By focusing on organization, technology, inventory management, space optimization, employee training, and continuous improvement, you can streamline operations, reduce costs, and increase productivity. By implementing best practices in efficient warehousing, you can create a more efficient and effective warehouse operation that supports the overall success of your business.

Best Practices for Inventory Management in Warehousing