Master the Art of Inventory Control

When it comes to streamlining inventory and reducing excess stock, mastering the art of inventory control is key. Inventory control is all about effectively managing the flow of goods in and out of your business to ensure that you always have the right amount of stock on hand.

One of the first steps in mastering inventory control is to conduct a thorough inventory audit. This involves taking stock of all the items in your inventory, noting their quantities, and identifying any excess or slow-moving items. By knowing exactly what you have on hand, you can make more informed decisions about what to order and when.

Another important aspect of inventory control is setting par levels for your products. Par levels are the minimum and maximum quantities of each item that you should have on hand at any given time. By setting par levels, you can ensure that you always have enough stock to meet customer demand without overordering and ending up with excess inventory.

In addition to setting par levels, it’s also important to regularly track and analyze your inventory turnover rate. This metric tells you how quickly your inventory is moving and can help you identify slow-moving items that may be tying up valuable warehouse space. By focusing on increasing your inventory turnover rate, you can avoid accumulating excess stock and free up cash flow for other areas of your business.

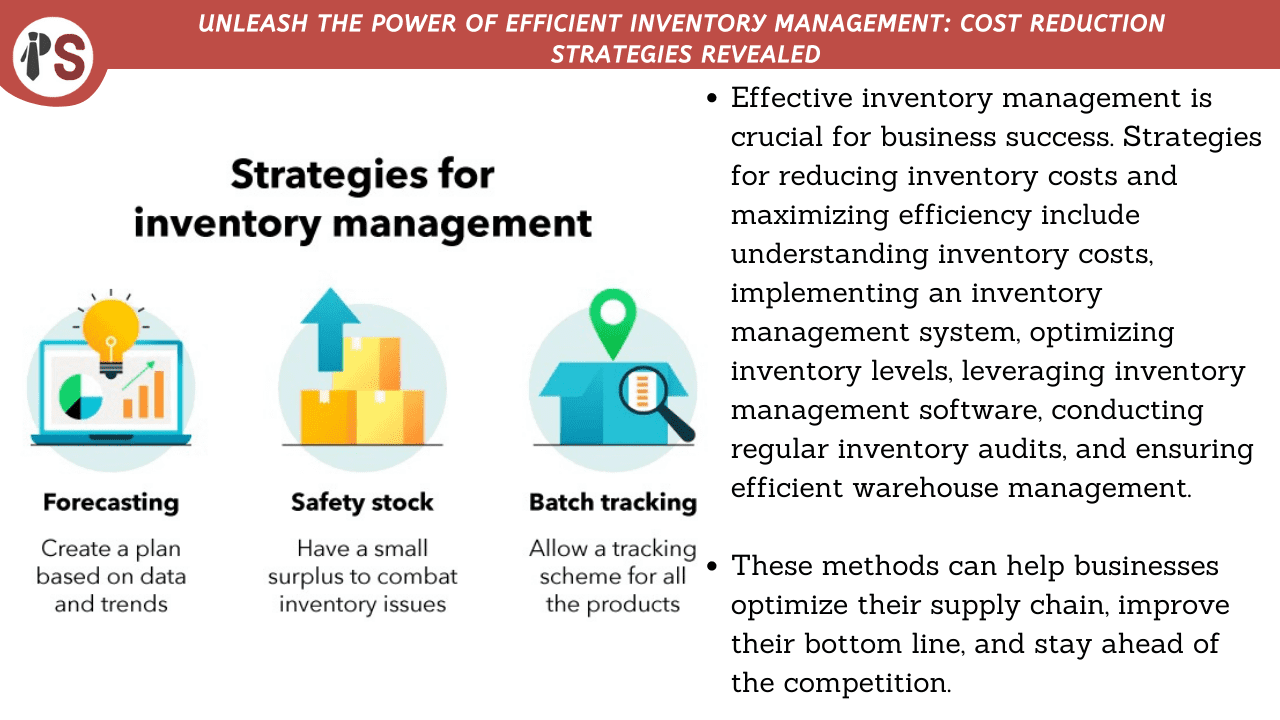

Image Source: professionalsaathi.com

Implementing an efficient inventory management system is another crucial step in mastering inventory control. An inventory management system can help you track your stock levels, automate reordering processes, and generate reports that provide insight into your inventory performance. By investing in an inventory management system, you can streamline your inventory processes and reduce the risk of stockouts or overstock situations.

Regularly reviewing and updating your inventory control processes is also essential for mastering the art of inventory control. By staying proactive and making adjustments as needed, you can ensure that your inventory levels are always optimized and aligned with your business goals.

In conclusion, mastering the art of inventory control is essential for reducing excess stock and streamlining your inventory processes. By conducting regular audits, setting par levels, tracking your inventory turnover rate, investing in an inventory management system, and staying proactive in your approach, you can optimize your inventory levels and improve the overall efficiency of your business.

Say Goodbye to Surplus Stock Today

Are you tired of seeing excess stock cluttering up your warehouse? Do you find yourself constantly trying to figure out what to do with all of that surplus inventory? It’s time to say goodbye to surplus stock today and streamline your inventory once and for all.

One of the biggest challenges that businesses face is managing their inventory effectively. Surplus stock can lead to a variety of issues, including wasted space, increased carrying costs, and decreased cash flow. But fear not, there are practical tips you can implement to reduce excess stock and improve your overall inventory management.

The first step to saying goodbye to surplus stock is to conduct a thorough inventory analysis. Take stock of what you have on hand, identify slow-moving or obsolete items, and determine the root causes of excess stock. By understanding why you have surplus inventory, you can take proactive steps to prevent it from happening in the future.

Once you have identified the items that are contributing to your surplus stock, it’s time to take action. Consider running promotions or discounting these items to move them out quickly. You can also bundle them with other products to create value for your customers and increase sales. By actively marketing and selling your surplus stock, you can free up valuable warehouse space and generate revenue at the same time.

Another practical tip for reducing excess stock is to establish better forecasting and ordering practices. By accurately predicting demand and ordering the right amount of inventory, you can prevent overstock situations from occurring in the first place. Consider investing in inventory management software or working with a third-party logistics provider to help streamline your ordering processes and improve overall inventory control.

In addition to improving forecasting and ordering practices, it’s important to optimize your inventory turnover rate. Slow-moving inventory ties up valuable resources and can lead to surplus stock. By focusing on increasing your inventory turnover rate, you can reduce excess stock and improve cash flow. Consider offering incentives for sales staff to promote certain products, running targeted marketing campaigns, or implementing a just-in-time inventory system to help move inventory more efficiently.

Lastly, don’t be afraid to get creative with your surplus stock. Consider donating excess inventory to charity or partnering with other businesses to create special promotions or bundles. You can also explore alternative sales channels, such as online marketplaces or pop-up shops, to reach new customers and move surplus stock quickly. By thinking outside the box and exploring different avenues for selling surplus inventory, you can say goodbye to excess stock and streamline your inventory management processes.

In conclusion, saying goodbye to surplus stock doesn’t have to be a daunting task. By implementing practical tips such as conducting a thorough inventory analysis, running promotions, improving forecasting and ordering practices, optimizing inventory turnover, and getting creative with surplus stock, you can reduce excess inventory and improve your overall inventory control. So why wait? Say goodbye to surplus stock today and take the first step towards streamlining your inventory for a more efficient and profitable future.

How to Reduce Excess Inventory: Tips and Techniques